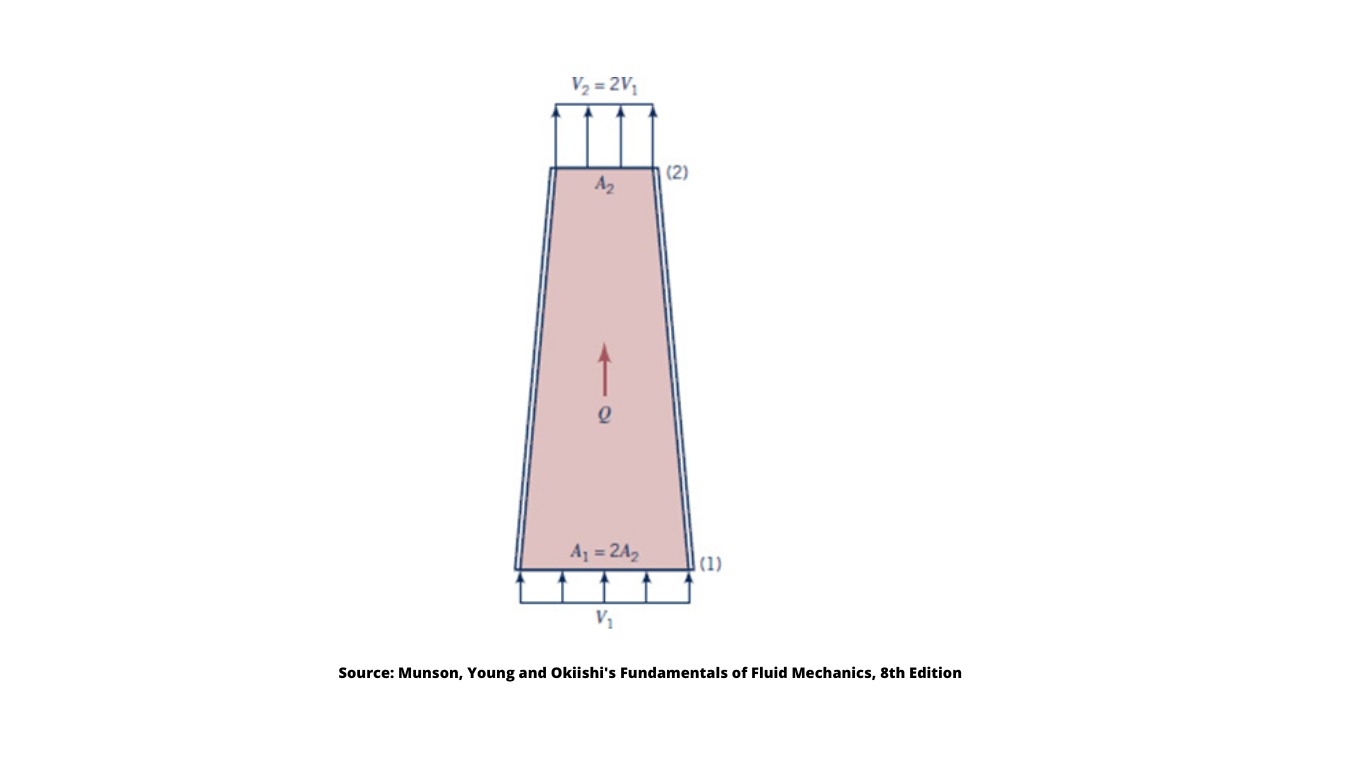

In this case, the diameter of the device is reduced, which will reduce the area of the transverse section and increase the speed. Depending on speed, the flow of water can be laminar or turbulent. For a lower speed, the flow is laminar or stable and predictable while for a higher speed, the flow is turbulent or irregular as well as disorderly, which will result in a difference in speed between the different particles. This type of flow will worsen the sound problems, load losses or in other words pressure losses and an acceleration of erosion of the device and other plumbing components which will not reach their complete lifespan. In addition, the nominal flow or the reference flow depends on the diameter of the component or the piping. For example, a 3-inch water meter (7.62 cm) placed upstream of the device has a nominal flow of 320 gallons per minute (GPM) while the 2-inch device (5.08 cm) has a nominal flow of 160 GPM. When the water with a speed of 320 GPM will go through the device, the water speed will increase to accommodate this flow which has exceeded the nominal flow of the 2-inch (5.08 cm) device.

The other consequence of reducing the diameter of the device is the pressure loss. The lack of pressure and flow will affect the quality of life. Indeed, a shower head that has low pressure is much less pleasant. Pressure loss per friction has a relationship proportional to the square of the speed. When the speed is doubled, the pressure loss is quadrupled. Pressure losses can be converted into meters with the length and diameter of the piping. Article A-2.6.3.1. paragraph 2 of Chapter III - Plumbing of the Construction Code describes the simplified methods to calculate the minimum pipe diameter which will avoid too high flow speeds and pressure losses in the drinking water network.

There are solutions to solve these problems. For the lack of pressure, an overpressure pump can be added to the network and acoustic insulation will be able to solve noise problems, but this goes against the original goal which was to save money. In addition, the backflow preventer device would need to be replaced since a high speed will cause a premature erosion.

In conclusion, installing a smaller backflow preventer device than that of the piping will not be less costly, on the contrary, the costs as well as the speed and pressure problems will increase.This is why it is not recommended to install a smaller size device.

[1] Munson, Young and Okiishi's Fundamentals of Fluid Mechanics, 8th Edition

[3] https://fccchr.usc.edu/_downloads/Cross%20Talk%20Archives/2005.23.3.pdf

We use cookies to understand how you use our site and to improve your experience. This includes personalizing content and advertising. By continuing to use our site, you accept our use of cookies, terms and conditions, privacy policy. Confused? Send us an e-mail.

I acceptWe use cookies

Respecting your privacy matters to us. We use cookies to personalize our content and facilitate your digital experience. Some cookies may be collected with your consent.

Essential

Essential cookies help make a website usable by enabling basic functions such as page navigation and access to secure areas of the website. The website cannot function properly without these cookies.

Performance

These cookies enable us to analyze navigation on our sites and improve their operation.

Customization

Preference cookies enable a website to remember information that modifies the behavior or appearance of the site, such as your preferred language or the region you are in.

Targeted advertising

These cookies help us limit the number of times you see an advertisement, personalize our offers and services according to your centers of interest, measure the effectiveness of an advertising campaign, and so on. They may be shared with our partners.

We use cookies

Respecting your privacy matters to us. We use cookies to personalize our content and facilitate your digital experience. Some cookies may be collected with your consent.