Imagine a company suffers water damage caused by a failure of their backflow prevention device (BPD), see this article for more information) in their plant and must then shut down all production and applications using water. This breakage could cost the company a fortune, even if the BPD is repaired within a reasonable time. How can we get around this unexpected problem? Indeed, by bypassing it!

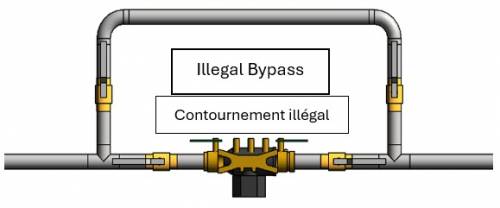

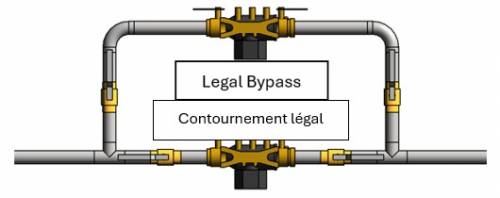

But what is a bypass? It is a secondary pipe that allows water to pass around the equipment, such as a BPD, to provide access for repairs or part replacement. The bypass is also known as a workaround. Often, a bypass is necessary to maintain operation in a factory, for example, but certain regulations are not respected, either through negligence or the owner’s lack of knowledge of the risks or even the consequences. In this case, BPDs have strict regulations that must be respected.

BPDs are selected based on their risk level and the location where they are connected.

According to bypass regulations, it is illegal to use this technique without installing a replacement BPD that meets the same risk level as the bypassed conduct. In other words, it must protect the network against the same hazard as the primary BPD

If a bypass is found to be non-compliant, the owner puts the public health at risk and may be liable to criminal prosecution [3]. In addition, if the illegal bypass is discovered during an inspection or as following an incident, the owner will be exposed to penalties that can be very serious. Significant fines can be imposed in varying amounts depending on several factors, such as decontamination costs or the impact on public health. These penalties can be added to repair costs, production losses and damage to the company's reputation. For example, according to the regulations of the City of Quebec, “If an offence is continuous, this continuity constitutes, day by day, a separate offence and the fine for this offence may be imposed for each day that the offence lasts”

In a factory, it is recommended to have a second BPD on the lines containing a BPD to avoid production shutdown in the event of a breakdown of the main BPD. Even if the cost of asecond BPD seems high, the risk of production shutdown and the associated financial losses justify the price in the long run.

It is also pay attention to the standards put in place for BPDs bypasses so as not to endanger the public or incur severe penalties. In addition, certain other best practices, such as having your BPDs inspected and certified annually by accredited testers and having padlocked valves on the bypass, will play a huge role in preventing problems.

1. CSA, Sélection et installation des dispositifs, 2023.

2. Régie du bâtiment du Québec, Protection des réseaux d'eau potable contre les raccordements croisés, 2019.

3. «Régie du bâtiment du Québec,» [En ligne]. Available: https://www.rbq.gouv.qc.ca/vous-etes/proprietaire-ou-exploitant/les-exigences-de-qualite-et-de-securite/dispositif-antirefoulement/.

4. «Règlements Ville de Québec,» [En ligne]. Available: https://reglements.ville.quebec.qc.ca/fr/document/ra/R.A.V.Q.%201401.

We use cookies to understand how you use our site and to improve your experience. This includes personalizing content and advertising. By continuing to use our site, you accept our use of cookies, terms and conditions, privacy policy. Confused? Send us an e-mail.

I acceptWe use cookies

Respecting your privacy matters to us. We use cookies to personalize our content and facilitate your digital experience. Some cookies may be collected with your consent.

Essential

Essential cookies help make a website usable by enabling basic functions such as page navigation and access to secure areas of the website. The website cannot function properly without these cookies.

Performance

These cookies enable us to analyze navigation on our sites and improve their operation.

Customization

Preference cookies enable a website to remember information that modifies the behavior or appearance of the site, such as your preferred language or the region you are in.

Targeted advertising

These cookies help us limit the number of times you see an advertisement, personalize our offers and services according to your centers of interest, measure the effectiveness of an advertising campaign, and so on. They may be shared with our partners.

We use cookies

Respecting your privacy matters to us. We use cookies to personalize our content and facilitate your digital experience. Some cookies may be collected with your consent.